Click this messge to hide it.

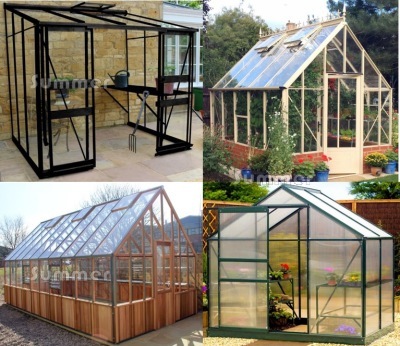

- We deliver a huge range of greenhouses throughout the UK.

- We also offer installation and base laying with selected greenhouses in many areas.

- We offer next day delivery with many of our polycarbonate greenhouse and some of our glass greenhouses.

- All prices include delivery and VAT.

Please click on the headings below to see information about the options available:

Use our Search Options to find your ideal greenhouse fast

We offer a huge choice of hundreds of greenhouses, each of which may be available in many sizes with a choice of features. Overall there are thousands of variations. With so much choice, it can be a challenge to find the best greenhouse for your needs. Our Search Options are designed to help.

FIND YOUR GREENHOUSE FAST

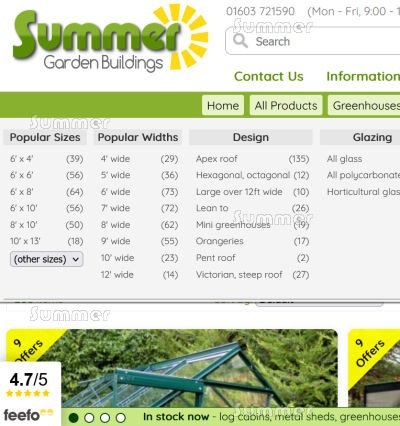

Whenever you browse our Greenhouses, the Search Options panel can be found at the top of the page. Even if you click on a greenhouse to view the details, you can recall the Search Options panel at any time if you click on the Greenhouses button at the top of the page.

PICTURE: The Search Options panel at the top of the page.

- Click on our Search Options to narrow your search.

- Scroll down to see information about each Search Option, including Popular Sizes & Widths, Design, Glazing, Framing, Walls, Doors and More Options.

- Try more than one search to be sure you find the best greenhouse for your needs.

- For most searches you only need to select one or two filters.

- Scroll down to see useful extra information about Installation Options and Baselaying Options.

- To see the correct local prices and availability we need to know your area. Click here to enter the FIRST HALF of your POSTCODE.

For information about other topics click here to see our Greenhouse FAQs.

Click here to see Popular Sizes

POPULAR SIZES and POPULAR WIDTHS

- We offer a huge range of sizes.

- You can use our Search Options to select a Popular Size or a Popular Width.

- If you want a specific size, search for the next smallest and the next largest size - your ideal greenhouse may be only an inch outside your search parameters.

- Remember to search for sizes and widths both ways. For example, search for 6'x8' and 8'x6'.

PICTURE: A 6'x8' (1.8m x 2.4m) mill finish aluminium greenhouse with W shaped spring clips.

A popular small greenhouse is 6'x8' (1.8x2.4m). A popular size for a large greenhouse is 8'x10' (2.4x3m). Many other sizes are available. A small greenhouse is recommended for a first time buyer if you want to keep your initial investment lower before committing. Otherwise, most experienced greenhouse owners buy the biggest size that fits comfortably within the available space in the garden. It is surprising how much you can grow in even a small greenhouse.

Click here to see Design Options

DESIGN

You can use our Search Options to browse a wide choice of designs.

Apex Roof Greenhouses

PICTURE: An 8'x10' (2.4x3m) apex roof cedar greenhouse with aluminium bar capping, guttering and downpipes.

The apex roof design features two sloping sides which meet in the middle. The roof slopes down from the highest point (the ridge) to the lowest point (the eaves). The apex roof design combines a strong angular design with a steep roof pitch to discharge rainwater quickly and easily. An apex roof also provides generous headroom inside.

Hexagonal and Octagonal Greenhouses

PICTURE: A 6'x8' (1.8m x 2.4m) octagonal aluminium greenhouse with bar capping.

Hexagonal greenhouses feature six side walls and octagonal greenhouses feature eight side walls. The hipped roof design features six or eight sloping sides which meet in the middle of the roof. The hipped roof slopes down from the highest point (the ridge) to the lowest point (the eaves). Although elaborate, hexagonal and octagonal designs are also functional, combining a strong angular design with a steep roof pitch to discharge rainwater quickly and providing generous headroom inside.

Large Greenhouses, over 12' wide

PICTURE: A large Victorian style orangery greenhouse.

Greenhouses over 12' wide (3.6m) are bigger than most domestic gardeners need, unless you are an experienced gardener with a large garden to look after. We offer many large greenhouses with a choice of aluminium or timber frames. Only our higher specification greenhouses are available in such large sizes. Our varied selection of larger greenhouses includes wide single span apex roof greenhouses, elaborate orangeries with complex valley roof designs and twin apex designs with twin gables and a central box gutter. Large greenhouses may include additional braces, struts and roof ties due to the wider roof spans involved. Longer box gutters include substantial support posts at intervals along the length of the gutter.

Lean To Greenhouses

PICTURE: A 6'x8' (1.8m x 2.4m) powder coated aluminium lean to greenhouse with bar capping and downpipe.

We offer a wide selection of lean to greenhouses with a choice of glass or polycarbonate glazing and aluminium or timber frames. The smallest lean to greenhouses are often described as a reach in greenhouse. Larger lean to greenhouses are sometimes used as an informal conservatory or sunlounge, especially at a site with a sunny aspect in the summer months.

If the height of the host wall is limited it is important to check the height available against the external ridge height of the lean to. The lean to ridge is the highest part of the roof, at the rear. At sites where the wall height is restricted it may be possible to excavate the base area in order to reduce the ground level. This is not always practical at every site as it depends on the surfaces and the ground levels. Be careful to ensure that the greenhouse door opening is unobstructed. If there are doors or windows in the host wall which are enclosed within the lean to you should also be careful to ensure that these can be opened freely.

View Lean To Greenhouses

Mini Greenhouses

PICTURE: A small reach-in lean to greenhouse with G shaped spring clips.

Most mini greenhouses or growhouses are too small to stand inside. Many are described as a reach in growhouse if you can reach everywhere from outside. Freestanding mini greenhouses often include several shelves at different heights so you can pack a lot of plants inside very efficiently. The most compact mini greenhouse of all is a cold frame, which is often small enough to be portable so you can carry it to plants in the vegetable garden and cover them. We classified our great value polytunnel as a mini greenhouse because it is compact but you can stand up in the middle so it is comparable with many cheaper greenhouses.

Click here to see Mini Greenhouses

Orangeries

PICTURE: A wooden orangery with extensive slatted staging all round.

The traditional design of an orangery harks back to the Victorian era when greenhouses first became popular. The orangery design features a decorative valley roof design with a T shape ridge and normally include a steep Victorian style roof. We offer a selection of striking orangeries with aluminium frames powder coated in a choice of colours or timber frames in cedar or thermally modified wood. Orangeries are not just an attractive design but also a great greenhouse to work in, with the door in the middle and a spacious doorway area. The high roof space provides extra growing space and the roof is strong enough to support plenty of hanging baskets.

View Orangery Greenhouses

Pent Roof

PICTURE: A 6'x8' (1.8m x 2.4m) pent roof greenhouse.

A pent roof is monopitch or on one plane, which may slope up or down from the front to the rear. The compact modern style is an unusual and distinctive design for a full size greenhouse. A pent roof is more commonplace as a roof for a small growhouse or mini greenhouse and sometimes the roof is hinged on one side so it can be lifted up for easy access.

Victorian, Steep Roof

PICTURE: An 8'x10' (2.4x3m) Victorian greenhouse with aluminium frame and bar capping.

Victorian style greenhouses have become increasingly popular in recent years as many customers want something more sophisticated than the standard functional greenhouses that were so popular in the past. These attractive high specification greenhouses are a stunning feature in the garden and a pleasure to work in. Victorian greenhouses feature a steep roof, whether you choose an apex roof or a Victorian orangery design. Other decorative features include hinged doors, brick dwarf walls and timber base panels. We offer a wide range of Victorian greenhouses with apex or orangery roof designs in cedar, pressure treated timber or thermally modified wood aswell as some very attractive and practical modern aluminium models.

Click here to see Glazing Options

GLAZING OPTIONS

Use our Search Options to choose from a selection of Glazing Options. The glazing is a fundamental part of any greenhouse so it is worth taking a little time to consider the most suitable glazing for your personal greenhouse.

All Glass Greenhouses

PICTURE: An 8'x10' (2.4x3m) mill finish aluminium greenhouse with horticultural glass.

Many years ago, when we started retailing greenhouses, toughened glass and polycarbonate were simply not available. The only option was horticultural glass. Also known as greenhouse glass, horticultural glass was considered the perfect solution for glazing a greenhouse. It was used in every greenhouse from a small domestic greenhouse to the largest commercial greenhouses. Horticultural glass is thinner than normal annealed or float glass with more blemishes and imperfections and it is much cheaper. It is also easier to cut. In those days it was made in only 3 sizes, 24"x24", 24"x18" and Dutch Light size (28.75" x 56" or 730mm x 1422 mm). Dutch Light glass was mainly used for commercial greenhouses. So all domestic greenhouses were designed to suit panes of glass 24" wide. In addition, most greenhouses featured small panes of glass with overlaps at the joins where algae could grow over time if it was not cleaned. Although greenhouse glass is made in a much wider range of sizes today, the majority of greenhouses are still made to suit 24" wide glass.

PICTURE: A W shaped spring clip.

Toughened safety glass became popular very quickly as soon as it was introduced, as did polycarbonate. Both are much safer, which is a big factor if children play in the garden, for dog owners or for people with an increased risk of falling. If safety is not a concern, greenhouse glass remains a great option. It is affordable and considering how brittle and fragile glass is, it is surprisingly strong and rigid when it is fitted in a greenhouse frame. With larger panes of greenhouse glass available today it is increasingly possible to buy a greenhouse glazed with greenhouse glass but with no overlaps.

Polycarbonate

PICTURE: Twinwall polycarbonate.

Twin wall polycarbonate is virtually unbreakable and very practical. With small children or pets around polycarbonate greenhouses are safer. Polycarbonate is also safer to handle during installation. Polycarbonate greenhouses provide a similar growing environment to glass greenhouses with better insulation properties and reduced glare. Polycarbonate also provides good insulation from frost and maintains a more even temperature for better plant growth. Twin wall polycarbonate also diffuses light to prevent scorching. Twin wall polycarbonate glazing is stronger than the flimsy single skin polycarbonate sheeting supplied with some greenhouses.

Polycarbonate greenhouses are often cheaper than a glass greenhouse, not because polycarbonate is any cheaper to buy than glass but because it is much cheaper to deliver. Glass is so fragile that delivery is difficult and expensive. By contrast polycarbonate is much lighter and it can be delivered on the national overnight parcel networks just as easily as any other parcel. This makes polycarbonate a popular choice with first time greenhouse buyers and anybody looking to keep the price down.

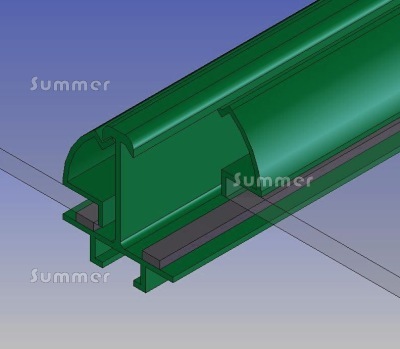

PICTURE: Clip-free polycarbonate glazing.

Many of our polycarbonate greenhouses include clip-free glazing. The polycarbonate panels are held in place continuously along the edges. The framing features integral full length grooves into which the edges of the glazing panels slide. The glazing panels are retained along the entire length of the framing. As a result, when the frame is fully assembled the glazing panels are more securely fixed and do not come out so easily. Unlike other glazing systems, no fixings, clips or capping strips are required.

View Polycarbonate Greenhouses

Toughened Glass

PICTURE: Broken toughened glass.

Toughened glass is the best glazing material for use in greenhouses. Toughened glass also strengthens the frame and it is heavy which helps to resist wind. Full height toughened glass is supplied in larger sizes than horticultural glass with no overlapping glass.

Toughened safety glass is around six times stronger than normal glass so it is less likely to break. When it does break, toughened glass breaks harmlessly into very small pieces. This makes toughened glass the best option for all the family including children, pets and the elderly. Greenhouses include a large area of glazing so the cost of toughened glass is higher, but the benefits are amplified.

View Toughened Glass Greenhouses

PICTURE: A T shaped glazing bar with clip in bar capping.

Bar capping is an attractive and effective alternative to glazing clips which is at least as strong but neater and easier to clean. The standard glazing clips are replaced with full length strips which hold the glass along its entire length. Bar capping cannot be fitted in a greenhouse with overlapping glass. This quality feature is only available with large pane glazing. Bar capping is often coloured to match the greenhouse frames.

Click here to see Framing Options

FRAMING OPTIONS

Use our Search Options to choose from a selection of Wall Options. We offer a choice of 2 distinctly different types of greenhouse, with either a wooden or an aluminium frame.

All Aluminium Greenhouses

PICTURE: A 8'x10' (2.4x3.0m) aluminium greenhouse with bar capping, viewed from behind.

Our aluminium greenhouse selection includes mill finish frames, which are a little cheaper, and powder coated aluminium. Some of our best powder coated greenhouses include a choice of colours. Cheaper glass greenhouses include glazing clips while higher specification glass greenhouses often include bar capping. Some of our best value greenhouses are aluminium with polycarbonate glazing, which are delivered from stock with next day delivery at very affordable prices. We also offer superb quality Victorian greenhouses and orangeries with sophisticated engineered aluminium components.

View All Aluminium Greenhouses

All Wooden Greenhouses

PICTURE: A 6'x6' (1.8x1.8m) octagonal cedar greenhouse.

We offer a wide range of wooden greenhouses made with pressure treated timber, thermally modified timber or cedar. Our range includes magnificent cedar Victorian greenhouses and orangeries with traditional features. By contrast, we also offer some superb modern hybrid greenhouses with cedar frames and powder coated aluminium bar capping. Competitively priced budget models are also available with clear styrene glazing. Many of our wooden greenhouses are available with a painted finish, with a choice of colours.

Aluminium, coloured

PICTURE: A 6'x8' (1.8x2.4m) aluminium greenhouse with a powder coated finish.

The powder coated finish of our coloured aluminium greenhouses is more attractive than the stark silver colour of mill finish aluminium greenhouses. The tough finish also has excellent weathering properties and retains its gloss and colour well. A good example of powder coating is the finish on your washing machine. Powder coated aluminium greenhouses have a similar finish.

Aluminium, silver

PICTURE: A 6'x8' (1.8x2.4m) aluminium mill finish greenhouse.

As the name suggests, mill finish is the colour of the aluminium after it has been milled and before it is painted. It is cheaper than painted aluminum but just as strong and durable. Many of our silver aluminium greenhouses also feature anodised frames, an additional protective coating with a silver finish. Anodisation keeps the greenhouse frame looking clean by reducing the rate at which the aluminium oxidises. Unpainted aluminium gradually oxidises, which appears as fine grey powder forms on the surface of the greenhouse. Oxidisation occurs quicker in areas of high pollution or in coastal areas. This is the aluminium's natural self protection and it does not harm the greenhouse.

Cedar

PICTURE: A cedar Victorian greenhouse with cedar base panels and aluminium bar capping.

Many of our best greenhouses feature cedar. We use Western Red Cedar, a naturally resilient timber which lasts longer than pine and other softwoods, even if never treated from new. It has deservedly earned an unrivalled reputation for its attractive appearance and extraordinary durability. It is the ideal choice for people who are too busy to maintain their greenhouse. This oily timber has a strong but pleasant aroma which repels insects. Cedar contains hardly any knots. If untreated it will fade to a silvery grey colour. Western Red Cedar is a sustainable resource from the well managed forests of North America.

View Cedar Greenhouses

Painted Timber

PICTURE: A 6'x8' (1.8x2.4m) painted greenhouse.

Some of our wooden greenhouses include a painted finish as standard while others include the paint finish as an option. The high quality microporous paint system is available in a choice of colours. Microporous woodstains are impervious to water but not to water vapour, which allows the wood to breathe.

Pressure Treated Timber

PICTURE: A 6'x8' (1.8x2.4m) pressure treated timber greenhouse.

Pressure treatment is a lifetime preservative treatment which will extend the lifespan of your greenhouse. The preservative is forced deep into the timber under pressure in a vacuum and penetrates below the surface. All other treatments apply a coat of stain to the surface of the timber only. With pressure impregnated timber, the chemicals are permanently bonded to the cell structure of the wood at a molecular level. Pressure treated wood is almost colourless except for a slight green tint caused by the copper content in the preservative. No further preservative treatment is ever needed. However, if you want a coloured finish for your greenhouse you can paint over pressure treated or tanalised wood with normal wood preservative in any colour.

View Pressure Treated Greenhouses

Thermally Modified Timber

PICTURE: An 8'x10' (2.4x3m) greenhouse with thermally modified timber.

Thermally modified timber is a beautiful natural material with a projected service life of 30 years or longer. Only heat and steam are used in the treatment process and no chemicals are added. It is a lifetime preservative treatment. The timber is gradually heated to a high temperature which permanently changes the physical properties of the wood. The resistance to decay and stability of the wood are significantly improved as are the insulation properties. The moisture content is reduced and resin is removed so it cannot seep out of the wood. The process was developed in Finland but it is based on ancient knowledge. For example, the Vikings knew that fencing poles with a burnt surface were more durable. The finished colour of the wood is an attractive brown which can be painted or stained just like any other wood. If the wood is left untreated it will fade over time to a silver grey colour in the same way as other timber.

View Thermally Modified Greenhouses

Click here to see Wall Options

WALL OPTIONS

Use our Search Options to choose from a selection of Wall Options.

Dwarf Wall

PICTURE: A wooden Victorian greenhouse with brick dwarf walls.

Dwarf walls can be built in your choice of brick or stone. You can choose engineering bricks for durability or you may be able to closely match the walls of your existing property. Dwarf walls offer maximum heat retention in the winter and are ideal for growing shade-loving plants such as ferns. Our prices do not include the dwarf walls. The greenhouse frames are prefabricated so the frame sizes cannot be adjusted to fit the dwarf walls. Instead the dwarf walls must be built to precisely the right size. Bricks are ideal but irregular natural stone may require carefully cropping. Air bricks can be built into the dwarf walls at regular intervals, which is an inexpensive way to provide low level ventilation. This will provide a healthy air flow through the greenhouse to ensure improved growing conditions and better crops.

Eaves Over 5ft High

PICTURE: An aluminium greenhouse with a comfortable 5'6" (1691mm) eaves height.

This Search Option allows you to browse only taller greenhouses, which are more comfortable to work in and better suited to growing certain plants. Higher specification greenhouses are normally taller but with many cheaper greenhouses a tall person may need to stoop. The eaves is the lowest part of the roof. If the eaves height is less than 5' (1.5m) a tall person can only stand in the middle part of a budget priced apex roof greenhouse.

Part Boarded Walls

PICTURE: An octagonal cedar greenhouse with part boarded walls.

Part boarded walls feature timber base panels with tongued and grooved matchboard cladding. The cladding boards are fully built into the greenhouse frame as an integral part which cannot be detached. Like dwarf walls, timber panelling offers better heat retention in the winter than fully glazed greenhouses. It is also ideal for growing shade-loving plants such as ferns.

Click here to see Door Options

DOOR OPTIONS

The doors are an important part of a greenhouse, partly for comfortable access but also for additional ventilation. In warm weather the doors can be open, providing important extra ventilation to supplement the opening windows.

Double Door

PICTURE: An 8'x10' (2.4x3m) aluminium greenhouse with no threshold double doors.

Double doors provide easy access in and out of the greenhouse with bulky items such as a bag of compost or large pots. A door with a low threshold or no threshold at all allows access for a wheelbarrow or trolley. Double doors may be sliding or hinged. Many aluminium greenhouses feature sliding doors. Victorian greenhouses normally include hinged doors

Hinged Door

PICTURE: A hinged door with a mortice lock and lever handles.

Traditional Victorian greenhouses normally feature hinged doors, either a single door or double doors in a larger greenhouse. Otherwise most greenhouses feature sliding doors.

Low Threshold Door

PICTURE: A low threshold door in an aluminium greenhouse.

A low threshold door makes access easier and more comfortable all the time, without stepping over the greenhouse base plinth. It is also safer when carrying a load. In addition, the low threshold also allows wheelbarrow access.

Click here to see More Options

MORE OPTIONS

The More Options menu allows you to narrow your search even more. Be careful when using narrow and specific searches. It is often a good idea to search with and without the search option set, just to be sure that you do not miss any suitable greenhouses. Useful search filters such as Best quality and Budget price allow you to focus on a limited selection to suit your requirements. You can also search for specific design features such as Internal partitions or Bar capping.

Express Delivery

PICTURE: A polycarbonate greenhouse which is available with next day delivery

Many of our polycarbonate greenhouses include free next day delivery. We also offer a range of glass greenhouses which are in stock and delivered within 2-3 days. You can order online and choose delivery on the next available weekday as you order, or you can pick another day that suits you or you can delay the delivery until you are ready and then pick your day. You can request a delivery day weeks in advance or you can wait to choose a day later.

Express delivery is included throughout mainland England, Wales, southern Scotland and central Scotland. Delivery to northern Scotland or offshore addresses may take a few days longer.

You can find accurate delivery information for any of our greenhouses in the online product description under the Delivery heading. The current delivery lead time and other details are listed. Although many of our best selling greenhouses include fast delivery, many others are not delivered for at least a few weeks and some of our best greenhouses may be a couple of months or more during our busiest periods. If you are not in a hurry you have the widest choice, but if you need your greenhouse fast we have a wealth of expertise in delivering these heavy and bulky products.

View Greenhouses with Express Delivery

Under 2.5m High

Under current planning regulations garden buildings which are within 2 metres of a boundary and over 2.5m high (8'2") normally require planning permission. Some larger apex or hipped roof greenhouses and orangery designs may be over 2.5m high. Large lean to greenhouses may also be more than 2.5m tall. You can normally find the height listed within our product descriptions. For more information about planning please see our FAQs.

Click here to see Optional Accessories

OPTIONAL ACCESSORIES

We offer a wide range of accessories so that you can customise your greenhouse with everything you need to finish it off and kit it out from one supplier at a competitive price.

Special offer package deals - bundles of accessories at reduced prices

Our package deals are a genuine opportunity to save money with a bundle of accessories delivered together at reduced prices as an extra incentive for you to buy our greenhouse in preference to buying from another supplier. With many of our greenhouses there is also a choice of some free offers and some low cost offers.

Base plinth

PICTURE: The corner of an aluminium base plinth

Most greenhouse cills are designed to overhang a base. A base plinth is normally required unless you build a brick or timber plinth or a concrete base to the exact size to suit for your greenhouse. In many cases the base plinth is an optional extra although sometimes it may be included in the price.

The base plinth makes installation much easier. It is designed to be a portable and largely prefabricated foundation beam. The plinth features a flat underside to spread the weight of the greenhouse over a larger area. The base plinth can be placed on any flat and level surface including soil, gravel, decking, concrete or paving slabs. It is best to prepare a perimeter footing of concrete or paving slabs for the base plinth to stand on. However, with care the base plinth can be placed on any surface including soil or gravel provided that the ground is flat and level. The base plinth is much cheaper if you buy it with the greenhouse compared with the price you pay to buy it later. This is because of transport costs. It is much cheaper for us to deliver everything you need in one delivery.

A few greenhouse cills can be laid directly on a flat surface and these do not require a separate base plinth, so this option is not offered.

Gutters and downpipes

PICTURE: A downpipe fitted to an aluminium greenhouse.

Many greenhouses include guttering options and with some of our best greenhouses guttering is included. Downpipe kits allow rainwater to be collected from the greenhouse roof for storage in a waterbutt. Natural rainwater is ideal for watering the plants in your greenhouse. Most aluminium greenhouses feature an integral gutter built into the eaves beam. Timber greenhouses often include separate gutters which are often mini gutters with a smaller diameter. It is often difficult to find downpipe components and other gutter accessories to match the exact gutter dimensions, especially with an aluminium greenhouse. Downpipe kits are normally unique to each aluminium greenhouse model and often the kit is the only practical solution if you want to collect rainwater.

Staging

PICTURE: 2 tier slatted staging.

Staging is a bench or table inside a greenhouse on which plants are placed in the best position to ensure that the plant grows well. For example, sun loving plants are staged on the top tier while shade loving plants are staged on the lower tier. In Victorian times greenhouse owners also used staging to display their best exotic plants prominently. Staging can also be used as an occasional potting bench.

Originally the design of greenhouse staging varied according to the likely use. For example, slatted staging suits plants which require watering and tray staging is designed to be filled with pea gravel. Nowadays greenhouse staging is normally just seen as a table. Slatted staging is the most popular staging nowadays because it drains easily if needed. If drainage is not required a potting bench is often preferred. People often choose both a staging table and a potting table, for maximum flexibility.

PICTURE: Slatted wooden 2 tier staging.

Timber staging lasts well inside a greenhouse, despite the damp environment. Some of our wooden staging features pressure treated timber throughout for extra durability. Pressure treatment is a lifetime preservative treatment.

PICTURE: Integral staging inside an aluminium greenhouse.

Integral staging is built into the greenhouse frame and made to the same lengths as the internal walls. Strong and durable slatted staging fits inside the greenhouse walls and fills the space neatly, maximising the growing area.

Potting Benches

PICTURE: A 2 tier wooden potting bench.

Although similar to a staging table, potting benches are slightly different. Designed primarily as a work surface for potting, the table top is solid and not slatted. The solid flat work surface is ideal for potting with retaining boards on three sides to hold more compost. The lower shelf provides more useful storage space. Many of our wooden potting benches feature pressure treated timber throughout for durability.

Seed Tray Frames

PICTURE: A 3 tier seed tray frame with 12 seed trays.

Seed tray frames are designed to suit standard seed trays. The frame features durable galvanized steel throughout. The plastic seed trays are normally included. You can use a multi-tier seed tray frame to bring on more seedlings in a compact space within your greenhouse .

Automatic vent openers

PICTURE: An automatic roof vent opener.

These openers automatically open and close roof vents and louvre vents in response to climatic conditions. Improved ventilation increases the air circulation through the greenhouse for better growing results. Automatic vent openers react to heat which ensures that in hot weather the vents open in your absence and then close again when it is cooler. The ease of opening is easily adjusted so that the vent opens more or less readily. Louvred ventilators provide a healthy air flow through the greenhouse to ensure improved growing conditions and better crops. Some plants such as alpines require more ventilation than others. If you are not yet sure which plants you are likely to grow improved ventilation will give you more versatility.

Louvre vents

PICTURE: A glass louvre vent with a manual opener.

A louvred ventilator is a great way to provide low level ventilation. The angle of the glass louvre blades is adjustable to control the ventilation. This can be adjusted easily by hand with the standard manual control. Alternatively, heat sensitive automatic openers are available which open and close the louvre blades to suit the temperature. When combined, louvre vents and roof vents provide improved air flow through the greenhouse.

Gas and Electric Heaters

We offer a range of gas and electric heaters. Our electric greenhouse heaters are IP24 rated. This means that the heater is protected against splashed water from any direction. Our electric heaters require a standard domestic 13 amp electricity supply. Our gas heaters feature adjustable output, flame failure devices and CO2 sensors.

PICTURE: A gas heater.

As an approximate guide, a 1.5kw heater will normally heat a greenhouse up to 6'x8' or provide frost protection only up to 6'x12'. A 3kw heater will heat a greenhouse up to 8'x12' or provide frost protection only up to 10'x15' in normal site conditions. Heating requirements vary greatly with less heat required in a sheltered location or a lean to and more heat required in Scotland than in Southern England. The design is also a factor. For example, dwarf walls improve the insulation and lean to greenhouses absorb warmth from the existing wall. Another factor is the materials used. Polycarbonate greenhouses retain heat better than glass and wooden greenhouses retain heat better than metal greenhouses. We recommend you to buy a bigger heater than you need - you can always turn it down. Internal partitions are often used in large greenhouses to create a smaller warm room which is cheaper and easier to heat.

WPC Composite Decking Kits

With our decking kits you can create your own decking base to a size and shape that fits your greenhouse and garden. Our superb quality WPC wood plastic composite decking closely resembles real wood, with the same look and feel. However, it is virtually maintenance free and it will never rot. Our WPC composite decking is a revolutionary material which provides all the benefits of real wood without the maintenance. Unlike real wood this synthetic wood is a weatherproof material with no knots, splinters, machining marks or other imperfections. It will never develop splits or shakes and no sap will ever ooze out of it. Occasional cleaning with soapy water normally restores the original appearance. If any dirt or stains become ingrained after prolonged neglect even the most stubborn marks can be cleaned with a pressure washer.

PICTURE: Our grey woodgrain WPC composite decking, ideal for a greenhouse base.

Click here to see Installation Options

We have always been interested in helping our customers at every stage of their garden building project. As a result, since we were established in 1981 we have developed a unique expertise. We offer expert advice and we can answer any query, however technical. We can also actively assist at every stage from making a planning application to advice about ongoing care and maintenance after completion. We can even help you with base preparation. Although fitting options are available in most areas, most of our greenhouses are designed for DIY assembly. If you prefer to install the greenhouse yourself we provide useful tips for DIY customers. We also provide a comprehensive range of low cost DIY base kits.

INSTALLATION OPTIONS

- Low cost installation is available as in option in most areas if you want to have your greenhouse professionally fitted.

- Some of our best value greenhouses are designed for DIY assembly and professional installation may not be available.

- Installation is not available with our polycarbonate greenhouses.

- The fitting service does not include base preparation. A flat and level base is required, which can be made using concrete, paving slabs, pressure treated timber or plastic base grids. In many areas a low cost base laying service is available as an option. We also offer heavy duty plastic base kits as a DIY option in all areas.

- Instructions are supplied to help with DIY assembly.

DIY Assembly

Our greenhouses are designed for DIY assembly with cut to size components. Only basic hand tools are required. DIY assembly is not difficult although it may take time with so many individual components. Most of our greenhouse frames are flat-packed with few if any prefabricated panels. Care is required when handling glass. Overall a DIY greenhouse may take some time to assemble, but the price is significantly cheaper. The cheap prices are welcomed by many customers, but there is a price to pay in terms of time. If you are a keen DIY enthusiast, self assembly is an excellent way to ensure a cheaper price and better value for money.

Optional Installation

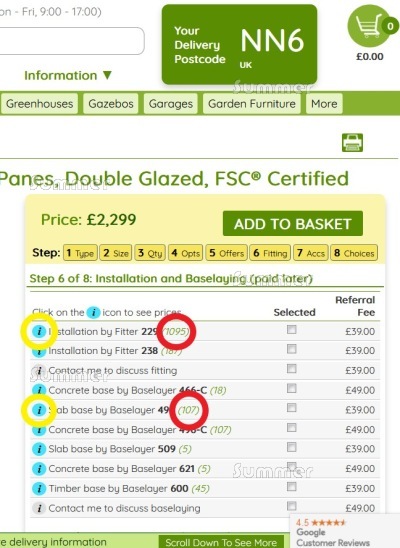

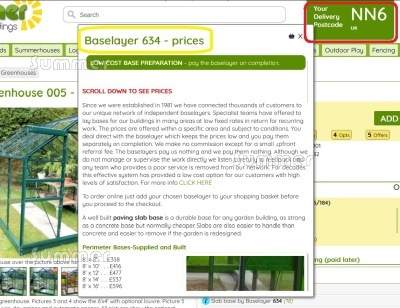

Since we were established in 1981 we have connected thousands of customers to our unique network of independent fitters. Specialist teams have offered to install our greenhouses in many areas at low fixed rates in return for recurring work. The prices are offered within a specific area and subject to conditions. You deal direct with the fitter which keeps the prices low and you pay them separately on completion. We make no commission except for a small upfront referral fee. The fitters pay us nothing and we pay them nothing. Although we do not manage or supervise the work directly we listen carefully to feedback and any team who provides a poor service is removed from our network. For decades this effective system has provided a low cost option for our customers with high levels of satisfaction.

Free Same Day Installation

Some of our best timber greenhouses include free installation. Over time regular feedback from fitters ensures that everything possible is done to simplify the installation and minimize delays on site. The doors are factory fitted complete with locks and handles. Often the glass and glazing beads are factory fitted. The result is a great quality greenhouse which is fitted quickly with few complications. Our free in house installation service is not just convenient, it is also your assurance of a quality greenhouse.

PICTURE: A greenhouse fitter finishing inside a mill finish aluminium greenhouse.

Click here to see Base Options

In addition to our unique network of installers, we also maintain a national network of baselayers who can build a base for many of our greenhouses. Although our network of baselayers covers many areas we are unable to offer blanket nationwide coverage. This is one of the reasons we developed our unique postcode based website, so that once you have set your delivery postcode you only see services and products available in your area.

BASE OPTIONS

- We can introduce you to independent baselayers in many areas offering to build paving slab bases, concrete bases and pressure treated timber bases.

- Alternatively, we can offer a choice of DIY base options if you want to build the base yourself.

- To see prices for any base options you need to be viewing a specific product.

- To see accurate prices and availability in your local area you need to first enter the first half of your postcode at the top of any page.

Independent Baselayers

Since we were established in 1981 we have connected thousands of customers to our unique network of independent baselayers. Specialist teams have offered to lay bases for our buildings in many areas at low fixed rates in return for recurring work. The prices are offered within a specific area and subject to conditions. You deal direct with the baselayer which keeps the prices low and you pay them separately on completion.

PICTURE: Click on the blue "i" symbols to see fitting and base laying prices (circled in yellow). See how many jobs each fitter or base layer has completed in brackets (circled in red).

We make no commission except for a small upfront referral fee. The baselayers pay us nothing and we pay them nothing. Although we do not manage or supervise the work directly we listen carefully to feedback and any team who provides a poor service is removed from our network. For decades this effective system has provided a low cost option for our customers with high levels of satisfaction.

A base completion date is specified when you order. This is normally four weeks after the order date unless an alternative date is agreed. The building is delivered shortly after this date. The completion date may be longer at busier times or due to holidays.

PICTURE: See where to set your delivery postcode (circled in red). See the pop-up window with each fitter or baselayer's prices (circled in yellow).

We regularly monitor the prices charged by our baselayers. In over 80% of cases the actual prices charged and the prices quoted above are exactly the same. However, there are circumstances in which additional charges may be required including, for example if site clearance is required, if the ground is not level or if access is restricted. We recommend the customer to confirm the price payable with the baselayer before work starts. We also recommend the baselayer to advise the customer at the earliest opportunity if the price is likely to exceed the prices quoted above.

Perimeter Bases

PICTURE: A perimeter base, made with paving slabs.

A perimeter base is a popular base option with greenhouse customers because it provides a solid foundation below the walls combined with soil inside the greenhouse. A fully paved or concreted base features paving slabs throughout with no soil inside the greenhouse and growing is only possible in seed trays, pots, planters and grow-bags.

A paving slab perimeter base features a single row of slabs around the perimeter only with soil inside the greenhouse. The row of slabs should be between 12" wide and 24" wide. The most popular slab size is 24"x24" but if available 18"x18" or 24"x12" slabs can also be used. If required a central path is available as an option. You should discuss any special requirements with the base layer at an early stage, before the materials are ordered.

A concrete perimeter base features a strip of concrete around the perimeter only with soil inside the greenhouse. The prices include a concrete strip up to 300mm wide and 450mm deep. A central concrete path is available as an option. A perimeter base is normally more expensive than full concrete, partly because shuttering is required to both the inside and outside faces of the concrete. In addition, for all but the largest sizes a perimeter base requires slightly more concrete.

Whether you choose a perimeter base or full base, any base should be at least a few inches larger than the greenhouse. Although the base can be built to the exact size of the greenhouse this option is not recommended.

PICTURE: A concrete perimeter base, made with shuttering.

Site Clearance and Preparation

A tape measure should be used to mark out the area of the base. The corners can be marked with canes or bricks. To ensure that the area is square the two diagonal measurements should be the same. The edges are easier to cut with a straight edge such as a wooden plank and a spade or turf cutter. All vegetation and roots should be removed otherwise as the organic material decomposes the base may settle unevenly. Large trees should only be removed by professionals. Small trees and shrubs can be removed by untrained people if care is exercised. To remove turf cut horizontally using a spade just below the roots at a depth of around two inches.

PICTURE: An area of lawn neatly excavated prior to base construction.

Excavation and Levelling

The soil can be levelled using a rake to even out minor peaks and troughs or a spade to dig away higher ground. Any large stones or roots should be removed. Before starting to lay the pavers a spirit level should be used to thoroughly check that the soil is level in all directions. The dimensions should also be checked with a tape measure. Extra time spent at this stage will be rewarded later. The base must be flat and level and large enough before proceeding to the next stage.

If possible allow space around a building to ensure comfortable access for installation and maintenance. If the base is sited near a wall or fence remember to allow for the roof overhang. Any overhanging trees or branches should be cut back.

Professional baselayers often charge extra for significant excavation, for the removal of existing obstructions such as existing buildings, garden walls, trees or compost heaps and for rubbish disposal if the spoil cannot be disposed of on site.

Paving Slab Bases

PICTURE: A paving slab base with smooth vibrated grey concrete slabs.

A well built paving slab base is a durable base for any garden building, as strong as a concrete base but normally cheaper. Slabs are also easier to handle than concrete and easier to remove if the garden is redesigned. Professional baselayers should include supplying and laying paving slabs on sand, mortar or concrete.

Concrete Bases

A concrete base is the most permanent and durable base for a garden building but a paving slab base is cheaper and more popular. A concrete base requires shuttering boards with a sturdy frame. Wet concrete is poured in and tamped smooth with a straight edge. A concrete base is often the best option for a building with no floor, such as a garage or a commercial workshop, or for a building which contains heavy machinery or equipment, such as a pump room or a hot tub enclosure. The concrete is normally finished a few inches above the ground. Inexpensive steel reinforcing can be placed within the concrete for extra strength at sites with poor ground conditions, for example where trees and shrubs have been removed.

PICTURE: Ripple finish concrete with smooth floated chamferred edges.

We recommend 100mm thick concrete with a thickened toe beam tapering to 300mm thick at the edges. An interval of up to seven days is advisable between the base and installation. However, if required in warmer weather it may be possible for installation to proceed with care after a shorter interval.

Decking Bases

PICTURE: Pressure treated timber decking boards on a substantial pressure treated timber platform.

A decking base is a popular option for greenhouses, being substantial, long lasting and well draining. Our WPC composite decking is low maintenance, tough, durable and completely impervious to water, making it an ideal solution for a greenhouse base. Timber decking is substantial pressure treated timber with a long life. Pressure treatment is a lifetime preservative treatment.

PICTURE: Our WPC composite decking kits make an ideal greenhouse base.

For any decking area a substantial platform base is required, which is normally constructed from substantial pressure treated timber although WPC joists are also available. A timber platform can be easily built over sloping ground without expensive excavation or levelling. A timber platform may also be a practical solution at a site where large trees have been removed. The platform should be finished a few inches above the ground allowing for better airflow than other base options. The support posts are concreted into the ground to ensure the base remains flat and level. If you choose quick setting concrete to hold the posts in place you can start installing your new building if you are careful within about half an hour.

PICTURE: A timber platform, before the decking boards are laid over it.

DIY BASE OPTIONS

Our durable eco-grid and eco-paving base kits are a practical and affordable alternative to slabs or concrete. Lightweight and easy to install within a few minutes, these 100% recycled polypropylene pavers simply click together with no fixings needed. The interlocking design ensures greater rigidity. Designed to spread weight, our plastic bases are self draining and fully relocatable, unlike paving or concrete. A fully paved base has no soil inside the greenhouse. Alternatively, a perimeter base features a single row of pavers laid around the perimeter of the greenhouse with soil inside. You can also add a footpath in the centre of a perimeter base.The base is normally at least 2" or 50mm larger than your building. Where space permits the base is normally laid full size but if required in a tight location our plastic pavers can be cut. Fast delivery within 3-5 days ensures that you can start work quickly.

Eco-Grid Bases

PICTURE: Eco-grids viewed from above (to the right) and below (to the left).

Eco-grids are recommended if the sub-base is soil, sand or pea shingle but not on hard surfaces such as concrete, because the underside is not flat. Integral pegs on the underside help to level the base grids more easily in soil or sand or shingle. Our eco-grid plastic bases can support up to 150 tonnes per square metre. We offer exactly the same eco-grids as driveways and carparks. Each eco-grid is 472mm x 472mm and 40mm thick with an immensely strong 60x60mm hexagonal cell structure. The kits include weed control membrane which is laid below the pavers. Extensive preparation is not normally required. First the ground is levelled and then the membrane is laid directly on the soil. The pavers are laid on the membrane or on a thin layer of sand or pea shingle. The pavers should be backfilled with gravel or pea shingle which is not supplied. Approximately 15-20kg of shingle is required per paver. We recommend checking this with your supplier or, if you can, buy less gravel than you need to start with.

Eco-Paving Bases

PICTURE: An eco-paving base, viewed from above, with two extra tiles upside down to show the underside.

Eco-paving is recommended if the sub-base is a hard surface such as concrete or paving slabs, because the pavers feature a flat and level underside. Our eco-paving is less brittle than concrete paving slabs, with a strong supporting structure. The surface looks and feels similar to pressed concrete slabs, with a slightly textured finish. Each eco-paver is 385mm x 385mm and 40mm thick. The pavers are quickly and easily easily laid over an existing hard surface. Eco-pavers can be used to build a perimeter base but care is required to provide a solid sub-base. Ideally the sub-base should be concrete or a similar hard surface. Laying eco-paving directly on soil is not recommended. Eco-pavers can be laid on a layer of gravel or pea shingle if it is carefully compacted and levelled. Each paver should be fully supported.

Thank you for shopping with Summer Garden Buildings - a leading UK specialist since 1981.