NN18

2 Jul, 2025 01:11:23

Alton Evolution Four-LT Lean To - Hybrid Cedar Greenhouse

- Optional installation is available

- Includes delivery in 10-12 weeks (or later if you wish)

- Prices fixed until Wednesday 9th July

Summary:

These modern hybrid lean to greenhouses have a 4'4" projection. The lengths are 4'5", 6'6", 8'6", 10'7" or 12'8". Cleverly combining the warmth and natural beauty of cedar with the performance and durability of profiled aluminium. The base plinth, threshold and door pelmet are aluminium with a choice of cedar or aluminium external capping. Luxury features include toughened safety glass as standard, low threshold doors, automatically opening roof vents and low level louvred vents. The aluminium components are powder coated grey to compliment the natural colour of the cedar when new and as it fades. The cedar is finished with a colourless preservative to enhance its natural beauty. Staging and high level shelving are available for potting and storage. Heaters, shading and many other accessories are also available to aid propagation and growing. Detailed instructions are supplied for DIY self assembly. We offer fitting as a low cost option in many areas.

The prices INCLUDE DELIVERY. Unlike others we do not add delivery charges at the checkout. Everything you need for assembly is supplied including instructions, fixings and glazing. Local INSTALLATION and BASELAYING services are also available in many postcodes. The prices include a free base plinth and toughened safety glass.

| Size | With Cedar Capping | Aluminium capping instead of cedar | Eco-grid base, 200 tonnes per m2, perimeter only | Eco-grid base, 200 tonnes per m2, fully paved | Eco-paving base, perimeter only | Eco-paving base, fully paved | Eco-paving footpath, 385mm wide |

|---|---|---|---|---|---|---|---|

| 4'4" x 4'5" | £1,999 | +£180 | £85 | £88 | £136 | £154 | £87 |

| 4'4" x 6'6" | £2,299 | +£210 | £97 | £107 | £154 | £203 | £97 |

| 4'4" x 8'6" | £2,599 | +£240 | £103 | £128 | £176 | £234 | £101 |

| 4'4" x 10'7" | £2,899 | +£270 | £110 | £137 | £194 | £283 | £123 |

| 4'4" x 12'8" | £3,199 | +£300 | £134 | £155 | £225 | £332 | £128 |

Specifications

- Western Red Cedar frame (a managed and replanted natural resource)

- All timber used in the construction of this greenhouse originates from sustainable forests

- 10 year frame guarantee

- All timber is treated by total immersion in a high quality preservative which is colourless to enhance the natural beauty of the wood

- Grey powder coated aluminium base plinth (makes greenhouse installation easy)

- Heavy duty ex 2"x2" and 2"x3" cedar framing (finished sizes 45mm x 45mm and 45mm x 70mm)

- Strong frame requires no diagonal braces

- Morticed and tenoned frame joints

- Morticed and tenoned doors and vents

- Toughened safety glass

- Puttyless glazing with substantial external capping screwed in to ensure the glass is tight fitting

- Full height glass where practical with no unsightly glass overlaps

- Grey powder coated aluminium gutter with downpipe

- Black round PVC downpipes and stopends

- Durable aluminium retaining clips ensure that the roof glass is retained securely at the eaves

- The glass overhangs into the gutter to ensure that the cedar framing is not exposed at the eaves

- The glass overhangs the base all round to ensure that the cedar framing is not exposed at low level

- Stainless steel fixing screws

- Aluminium base fixing bolts

- Roof vents are fitted as standard with automatic openers which react to heat to ensure that in hot weather the window ventilates in your absence

- 1 free roof vent and 1 low level louvre vent included with 4'4"x4'5", 4'4"x6'6" and 4'4"x8'6" greenhouses

- 2 free roof vents and 2 low level louvre vents included with 4'4"x10'7" and 4'4"x12'8" greenhouses

- Flashing between the wall and the greenhouse is not supplied

- Half boarded single sliding door with lockable catch

- Low threshold doorway for easy access

- Grey powder coated aluminium door threshold

- Grey powder coated aluminium pelmet threshold

- Durable aluminium running gear ensures smoother door operation and longer lasting performance

- No exposed wood at the top of the door

- No door timber in contact with the ground

- Eaves height 5'7" (1700mm) including base plinth

- Ridge height 7'11" (2400mm) including base plinth

- Door height 6'2" (1890mm)

- Door width 1'10" (560mm)

- This building is easy to deliver if access is restricted - all sections will pass through a normal single door

THIS ALTON EVOLUTION GREENHOUSE: Alton greenhouses have been a traditional favourite with UK gardeners for many years. In 2013 this wonderful range was thoroughly reviewed and modernised. The result is stronger and longer lasting greenhouses with a more sophisticated dry glazing system, improved door performance and more controllable ventilation. At the same time the natural beauty of the high grade cedar has been improved with thicker and stronger framing with less bracing and a modern colourless finish. Behind the striking new look most of the popular old features have been retained including toughened safety glass as standard, no overlapping glass and low threshold doors. Some of the old features have been significantly enhanced especially the gutters, the staging, the shelving and the low level ventilation. The result is an even better range of greenhouses which evolved from the old market leader, hence the new models are known as the Alton Evolution.

HYBRID ALUMINIUM AND CEDAR CONSTRUCTION: This modern hybrid greenhouse combines the warmth and beauty of cedar with the rigidity and durability of extruded aluminium. Intelligent use of aluminium protects the timber and prolong its life. The base plinth, the door threshold and the door runners are all aluminium which ensures no direct contact between any timber and the ground. In addition, the aluminium door track protects the top of the door from the elements. Almost all of the cedar framing is enclosed and internal which ensures lasting strength and good looks. The aluminium components are powder coated in a shade of grey which compliments the cedar when new and as it fades.

HEAVY DUTY CEDAR FRAME: The cedar frame features substantial ex 2"x2" (45x45mm) and ex 3"x2" (70x45mm) timber which requires no additional bracing. The design combines traditional joinery features such as morticed and tenoned joints with modern production techniques to ensure great strength and fast installation. All cedar is treated with a colourless preservative which provides a waterproof seal without hiding the beautiful natural colour of the cedar. Rounded edges enhance the soft natural feel of the wood.

DURABLE ALUMINIUM COMPONENTS: Most of the aluminium components are used in the parts of the greenhouse which are the wettest. This includes the base, the door threshold, the door track and the gutters. In addition, extruded aluminium provides better performance and durability for moving parts such as the door runners, the roof vent hinge mechanism and the louvre vent mechanism. The aluminium components are powder coated in a shade of grey which has been chosen to complement the appearance of cedar when it is new but also as it fades to a silvery grey colour.

WESTERN RED CEDAR: Western Red Cedar is a naturally resilient timber which lasts longer than pine and other softwoods, even if never treated from new. It has been widely used in construction for over a century. During this time cedar has deservedly earned an unrivalled reputation for its attractive appearance and extraordinary durability. It is the ideal choice for people who are too busy to maintain their garden building. This oily timber has a strong but pleasant aroma which repells insects. Cedar contains hardly any knots. If untreated it will fade to a silvery grey colour. Western Red Cedar is a sustainable resource from the well managed forests of North America.

POWDER COATED ALUMINIUM: The powder coated finish is more attractive than the stark silver finish aluminium greenhouses. The tough finish also has excellent weathering properties and retains its gloss and colour superbly. A good example of powder coating is the finish on your washing machine. Powder coated aluminium greenhouses have a similar finish.

TOUGHENED GLASS: Toughened glass is the best glazing material for use in greenhouses. It is around 6 times stronger than normal glass so it is less likely to break and when it does break toughened glass breaks into harmless small pieces. This makes toughened glass the best option for all the family including children, pets and the elderly. Toughened glass also strengthens the frame and it is heavy which helps to resist wind. Although size limits apply, toughened glass panes are longer than horticultural glass, with no overlapping glass and fewer joins. Where required, joins are neat in-line H-profile joins. Greenhouse glass is subject to lower visual standards than other more expensive glass and may include blemishes or imperfections which do not adversely affect the performance.

BASE PLINTH: The base plinth makes installation much easier. It is designed to be a portable and prefabricated foundation beam. The plinth features a flat underside to spread the weight of the greenhouse over a larger area. The base plinth can be placed on any flat and level surface including soil, gravel, decking, concrete or paving slabs. It is best to prepare a perimeter footing of concrete or paving slabs for the base plinth to stand on. However, with care the base plinth can be placed on any surface including soil or gravel provided that the ground is flat and level.

GREENHOUSE LOCATION: Ideally your greenhouse should have a clear space at least 18" wide on all sides, if possible. This ensures easy access for both installation and future maintenance. In reality this is often not practical and at many sites it is not needed. A reduced clearance is often possible on one or two sides. You should cut back or remove any nearby shrubs and trees. Remember to allow for future growth. The best position for a lean to greenhouse is against a south facing wall and outside the shadow of nearby buildings and trees. A sheltered position is best otherwise additional screening may be advisable. Plants need plenty of water so your greenhouse should be close to a water supply and the site should be well drained.

LENGTH AND WIDTH: Sizes are sometimes rounded to the nearest nominal size for ease of reading but the correct external wall sizes are listed alongside the price. The first dimension listed is the width and the second dimension is the length. The width refers to the sloping walls to each side. The length refers to the front wall. The sizes listed are the external wall sizes. These sizes do not include the roof overhang. Many other suppliers quote the overall roof size which is much larger. All sizes are approximate.

Options

- The sliding door can be positioned in either end and this does not need to be specified when ordering

- Choice of cedar or aluminium external capping

- Grey powder coated aluminium staging, length to suit the greenhouse

- Grey powder coated aluminium high level shelving, length to suit the greenhouse

- Freestanding staging and potting tables

- Additional roof vents with automatic openers

- Additional louvred vents

- Automatic louvre openers

- Attractive wooden slatted water butts

- Internal roller blinds - to protect your plants in a summer heatwave!

- Potting trays

- Seed trays

- Cedar cold frames

- Propagators

- Electric and gas heaters

- Thermometers and soil gauges

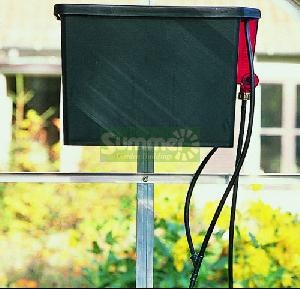

- Automatic watering systems

CEDAR CAPPING: The external capping protects the main structural framing timber which remains dry in all weather. Cedar capping provides a softer and more traditional appearance. The natural durability of cedar combined with the use of aluminium in vulnerable areas ensures that cedar capping will last. The cedar capping is treated with a colourless preservative.

ALUMINIUM CAPPING: With aluminium capping specified, there is hardly any external timber. The appearance is more modern but the overall impression remains of a beautiful cedar greenhouse. With the main structural timbers protected from the elements, the aluminium capping provides the ultimate performance with the look and feel of cedar and the durability of aluminium. The aluminium capping is powder coated grey.

VENTILATION: Improved ventilation increases the air circulation through the greenhouse for better growing results. Automatic openers react to heat which ensures that in hot weather the vents open in your absence and then close again when its cooler. Louvred ventilators provide a healthy air flow through the greenhouse to ensure improved growing conditions and better crops. Vents are an integral part of the greenhouse so it is easier to fit extra vents at the outset. Some plants such as alpines require more ventilation than others. If you are not yet sure which plants you are likely to grow improved ventilation will give you more versatility.

BUILT IN ALUMINIUM STAGING: Our built in aluminium staging provides a useful work surface and additional growing space in your greenhouse. It is bolted to the greenhouse frame and adjustable to any height. There are no legs below the staging, which gives you more flexible storage space. The staging is made to the same lengths as the internal walls to ensure a neat fit when a full length staging is specified. For this reason the actual length of the staging may be slightly less than the nominal lengths listed.

BUILT IN SLATTED SHELVING: The built in slatted shelving matches the staging although it is not as wide. It is fixed to the greenhouse frames and provides extra growing space or useful extra storage. The shelving is adjustable to any height but it is often fitted at a higher level than the staging. Often the shelving is fitted above the staging where it provides handy storage at your fingertips directly above the main growing area. The shelving can also be fitted at waist height for use as narrow staging on one or both sides. The shelving is made to the same lengths as the internal walls to ensure a neat fit when a full length shelving is specified. For this reason the actual length of the shelving may be slightly less than the nominal lengths listed.

HEATERS: We offer a huge range of heaters so whatever your specific requirements we have a heater to do the job. Our electric heaters require a standard domestic 13 amp electricity supply. Our propane gas heaters require permanent trickle ventilation when in use. As an approximate guide, a 3kw heater will heat a greenhouse up to 8'x12' or provide frost protection only up to 10'x15' in normal site conditions. A 1.5kw heater will normally heat a greenhouse up to 6'x8' or provide frost protection only up to 6'x12'. Internal partitions are often used in large greenhouses to create a smaller warm room which is cheaper and easier to heat.

HEATING REQUIREMENTS: Heating requirements vary for several reasons. Location is one factor with more heating required in Scotland than in southern England and less heating required in a sheltered position. The design is also a factor. For example, dwarf walls improve the insulation and lean to greenhouses absorb warmth from the existing wall. Another factor is the materials used. Polycarbonate greenhouses retain heat better than glass and wooden greenhouses retain heat better than metal greenhouses. We recommend you to buy a bigger heater than you need - you can always turn it down.

ROLLER BLINDS: Shading is normally required on one side of the greenhouse only, the sunny side. Attractive and versatile, these fully retractable and tensioned roof roller blinds will protect your plants. Internal blinds also provide significant insulation and reduce winter heating costs. Each blind provides shade for one glazing section. Roller blinds are normally fitted to one side of the roof. This protects against the strongest sunlight from directly overhead. If extra shading is required the blinds can be fitted just as easily in the walls of the greenhouse. The length of a blind can be reduced easily if required to allow for protruding vents handles. All fittings are supplied. DIY installation requires only a spanner.

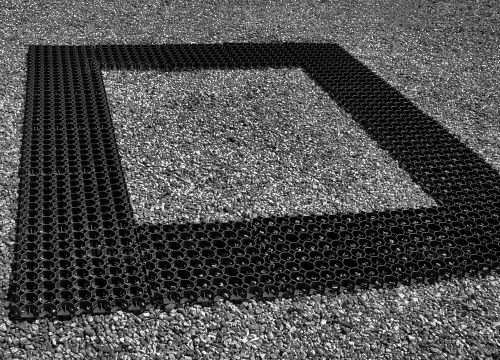

RECYCLED PLASTIC BASE KITS: Our durable eco-grid and eco-paving base kits are a practical and affordable alternative to slabs or concrete. Lightweight and easy to install within a few minutes, these 100% recycled polypropylene pavers simply click together with no fixings needed. The interlocking design ensures greater rigidity. Designed to spread weight, our plastic bases are self draining and fully relocatable, unlike paving or concrete. A fully paved base has no soil inside the greenhouse. Alternatively, a perimeter base features a single row of pavers laid around the perimeter of the greenhouse with soil inside. You can also add a footpath in the centre of a perimeter base. The base is normally at least 2" or 50mm larger than your building. Where space permits the base is normally laid full size but if required in a tight location our plastic pavers can be cut. Fast delivery within 3-5 days ensures that you can start work quickly.

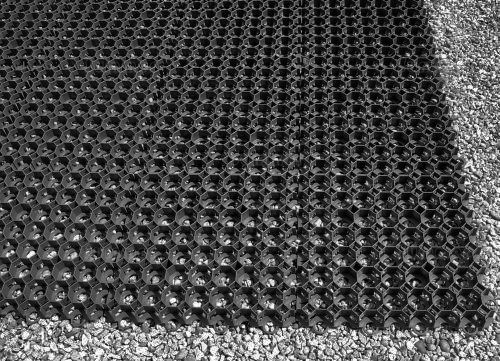

ECO-GRID BASE KITS: Eco-grids are recommended if the sub-base is soil, sand or pea shingle but not on hard surfaces such as concrete, because the underside is not flat. Integral pegs on the underside help to level the base grids more easily in soil or sand or shingle. Our eco-grid plastic bases can support up to 200 tonnes per square metre. We supply exactly the same eco-grids for use in driveways and carparks. Each eco-grid is 472mm x 472mm and 40mm thick with an immensely strong 60x60mm hexagonal cell structure. The kits include weed control membrane which is laid below the pavers. Extensive preparation is not normally required. First the ground is levelled and then the membrane is laid directly on the soil. The pavers are laid on the membrane or on a thin layer of sand or pea shingle. The pavers should be backfilled with gravel or pea shingle which is not supplied. Approximately 15-20kg of shingle is required per paver. We recommend checking this with your supplier or, if you can, buy less gravel than you need to start with.

ECO-PAVING KITS - BASES, FLOORS AND FOOTPATHS: This durable floor kit is a practical and affordable alternative to slabs or concrete. Easy to install within a few minutes, these recycled polypropylene pavers simply click together with no fixings needed. The pavers are easily prised apart so the floor is even quicker to remove if required. Eco-paving is recommended if the sub-base is a hard surface such as concrete or paving slabs, because the pavers feature a flat and level underside. Our eco-paving is less brittle than concrete paving slabs, with a strong supporting structure. The surface looks and feels similar to pressed concrete slabs, with a slightly textured finish. Each eco-paver is 385mm x 385mm and 40mm thick. The pavers are quickly and easily laid over an existing hard surface. Laying eco-paving directly on soil is not recommended. Eco-pavers can be laid on a layer of gravel or pea shingle if it is carefully compacted and levelled. The kits include weed control membrane which can be laid below the pavers. Each paver should be fully supported. Eco-pavers can be used to build a perimeter base but care is required to provide a solid sub-base. Ideally the sub-base should be concrete or a similar hard surface.

The Eco-paving internal floor sometimes fits comfortably inside the greenhouse with a few inches to spare. Sometimes it is overlength but it can be cut to fit. The finished floor is self draining and suitable for wheelbarrows and wheelchairs. Laying eco-paving directly on soil is not recommended. Eco-pavers can be laid on a layer of gravel or pea shingle if it is carefully compacted and levelled. Each paver should be fully supported.

A durable Eco-paving footpath is inexpensive and easy to install inside any greenhouse. The footpath is normally laid inside the greenhouse after the assembly is completed. The kit sometimes fits comfortably inside the greenhouse with a few inches to spare. Sometimes it is overlength but it can be cut to fit. Designed to spread weight, the finished floor or footpath is self draining and suitable for wheelbarrows. Laying eco-paving directly on soil is not recommended. Eco-pavers can be laid on a layer of gravel or pea shingle if it is carefully compacted and levelled. Each paver should be fully supported.

Delivery

- Delivery is normally between 10 and 12 weeks after order.

- Our greenhouse prices include all delivery charges - unlike others we do not add delivery charges during the checkout process.

SPECIALIST DELIVERY SERVICE: These greenhouses are normally delivered by specialist trained staff in dedicated vehicles. The benefits of a specialist delivery service include less damage, larger panels, heavier construction and helpful drivers who will carry your greenhouse to your chosen storage place.

Ordering/Payment

- All prices include VAT.

- Pay only 30% deposit when you order this greenhouse by phone or online.

ORDER ONLINE: You can pay with a debit or credit card. We also accept password protected online payments using Verified by VISA or Mastercard SecureCode. You can pay in full or pay a deposit only. You can pay a minimum 30% deposit with order or pay a bigger deposit if you prefer.

METHODS OF PAYMENT: We accept most major credit cards and debit cards including VISA, MasterCard, VISA Debit and MasterCard Debit. We also accept secure online payments using Verified by VISA or MasterCard SecureCode. We do not accept American Express or Diners Club cards at present.

SCHOOLS, COUNCILS AND BUSINESSES: We supply many schools, local councils and businesses both large and small. The prices and terms are the same so you can order online if you wish. If you want to pay by BACS transfer or company cheque please email us.

Installation

- Low cost installation available in many areas

- Pay separately on completion

THOUSANDS OF SATISFIED CUSTOMERS: Since we were established in 1981 we have connected thousands of customers to our unique network of independent fitters and baselayers. Specialist teams have offered to install our buildings or lay bases in many areas at low fixed rates in return for recurring work. The prices are offered within a specific area and subject to conditions. You deal direct with the fitter or baselayer which keeps the prices low and you pay them separately on completion. We make no commission except for a small upfront referral fee. The fitters and baselayers pay us nothing and we pay them nothing. Although we do not manage or supervise the work directly we listen carefully to feedback and any team who provides a poor service is removed from our network. For decades this effective system has provided a low cost option for our customers with high levels of satisfaction.

LOW PRICES FOR BASELAYING AND INSTALLATION: Low cost fitters and baselayers are available in many areas. To see the prices in your local area just enter the first half of your postcode at the top of every page or CLICK HERE. All of the specialist teams available in your area are listed alongside the building prices. To see their prices and conditions just click on the blue "i" symbol next to each team. To order online just add your chosen fitter or baselayer to your shopping basket before you proceed to the checkout.

NO FITTERS IN YOUR AREA? If you cannot see any fitters or baselayers in your area please contact us. We can often obtain a competitive quote from a team who is willing to travel a bit further. If you experience any other problems, for example entering your postcode or finding the fitting prices just contact us.

FITTERS & BASELAYERS REQUIRED - REGISTER FREE: Give your business a boost - we can put you in touch with customers in your local area! We need more fitters and base layers in all areas across England, Scotland and Wales. Register now - its free! It only takes a few minutes to register. Just CLICK HERE to apply online.

Features and Accessories

Minimum base sizes

Additional doors

Ventilation

Automatic vent openers

Greenhouse base preparation and other information

GREENHOUSES - Greenhouse Base - Eco-grid base, 200 tonnes per m2, fully paved

GREENHOUSES - Greenhouse Base - Eco-grid base, 200 tonnes per m2, perimeter only

GREENHOUSES - Greenhouse Base - Eco-paving base, fully paved

GREENHOUSES - Greenhouse Base - Eco-paving footpath, 385mm wide

GREENHOUSES - Greenhouse Base - Eco-paving base, perimeter only

Steel potting benches

Internal shading

Seed tray frames

Full length built in shelving

Heavy duty steel 2 tier staging

Full length built in staging

Hanging basket brackets and plant supports

Close up photos

Wooden planters

Wooden potting tables

Wooden 2 tier staging

Other information

Cedar cold frames

Irrigation kits

Insulation

Thermometers and soil gauges

Electric heaters

Gas heaters